8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Name Applicable industries Desktop Screwdriver Robot Electric Bicycle Assembly Trends in Software for Screw Automation body { font-family: Arial, sans-serif; line-height: 1.6; margin: 20px; color: #333; } h1 { color: #0056b3; font-size: 28px; margin-bottom: 10px; } h2 { color: #0056b3; font-size: 22px; margin-top: 25px; margin-bottom: 10px; } p { margin-bottom: 15px; text-align: justify; } ul { margin-top: 0; padding-left: 20px; } li { margin-bottom: 8px; } .highlight { background-color: #f0f8ff; padding: 15px; border-radius: 5px; margin: 15px 0; } Trends in Software for Screw Automation The landscape of industrial automation is continuously evolving, and screw automation is no exception. While hardware components like feeders, drivers, and manipulators form the physical backbone of these systems, the software that controls them is increasingly becoming the critical differentiator. Modern software solutions are transforming screw automation from a simple repetitive task into a sophisticated, data-driven, and intelligent process. This article explores the key software trends shaping the future of screw automation systems. Rise of Intelligent Process Control Traditional automation software focused primarily on basic motion control and sequencing. Today, advanced algorithms enable intelligent process control. Software can now dynamically adjust parameters in real-time based on feedback from vision systems, torque sensors, and other inputs. For instance, if a screw is cross-threaded, the software can detect the anomaly through torque patterns, halt the process, and alert operators or even initiate a corrective action routine. This significantly reduces error rates and prevents potential damage to products and equipment. Integration of AI and Machine Learning Artificial Intelligence (AI) and Machine Learning (ML) are moving from buzzwords to practical tools on the factory floor. In screw automation, ML algorithms are used to analyze vast amounts of process data—such as torque-angle curves, insertion times, and error logs—to predict maintenance needs, optimize tightening strategies for different materials, and identify subtle patterns that precede failures. This shift from reactive to predictive maintenance minimizes unplanned downtime and maximizes production efficiency. Seamless IIoT and Data Connectivity The Industrial Internet of Things (IIoT) is a major driving force. Modern screw automation software is designed to be inherently connected. It seamlessly integrates with factory-wide Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) software, and cloud platforms. This connectivity allows for centralized monitoring and management of multiple automated screwdriving cells from a single dashboard. Real-time data on production counts, quality metrics, and machine status can be accessed remotely, facilitating better decision-making and streamlined operations. Enhanced User Experience with HMI User interfaces are becoming more intuitive and powerful. Touch-screen Human-Machine Interfaces (HMIs) are now standard, featuring rich graphics, simplified programming wizards, and step-by-step guidance. This reduces the training required for operators and technicians, allowing them to set up new products, change parameters, and troubleshoot issues quickly. The focus is on making complex automation accessible without requiring deep programming expertise. Cybersecurity as a Priority As systems become more connected, the importance of robust cybersecurity in automation software has skyrocketed. Leading software platforms now incorporate hardened security features, including encrypted data communication, role-based access control, and secure boot processes. Protecting the integrity of the manufacturing process and safeguarding sensitive production data from cyber threats is now a fundamental requirement, not an afterthought. Adaptive Flexibility and Scalability The demand for high-mix, low-volume production requires software that is both flexible and scalable. Software platforms are now designed to be easily adaptable to new product designs. Features like recipe management allow for quick changeovers between different screw types, sizes, and tightening specifications simply by loading a saved file. Furthermore, the software architecture is often modular, allowing capabilities to be scaled up as production needs grow. In Conclusion The evolution of software is fundamentally enhancing the capabilities of screw automation systems. The trends point towards smarter, more connected, and user-friendly platforms that not only drive efficiency and quality but also provide valuable insights and adaptability. For companies looking to upgrade their assembly lines, investing in a modern software-driven screw automation solution is a strategic step towards building a more resilient, efficient, and intelligent manufacturing operation.

body { font-family: Arial, sans-serif; line-height: 1.6; color: #333; margin: 20px; } h1 { color: #2c3e50; font-size: 28px; margin-bottom: 20px; } h2 { color: #34495e; font-size: 22px; margin-top: 25px; margin-bottom: 15px; } p { margin-bottom: 15px; text-align: justify; } ul { margin-bottom: 15px; padding-left: 20px; } li { margin-bottom: 8px; } strong { color: #16a085; } The Future of Screw Locking Robots in Industry 4.0 The Fourth Industrial Revolution, widely known as Industry 4.0, is fundamentally reshaping manufacturing landscapes across the globe. At the heart of this transformation lies the integration of smart automation, data exchange, and cyber-physical systems. Among the many technological advancements driving this change, screw locking robots are emerging as a critical component in modern assembly lines. These sophisticated machines are no longer mere tools for repetitive tasks; they are evolving into intelligent systems that enhance precision, efficiency, and connectivity in smart factories. Intelligent Automation and Precision Engineering Traditional screw fastening processes often relied on manual labor or basic automated systems, which were prone to inconsistencies, errors, and fatigue. The next generation of screw locking robots, however, leverages advanced technologies such as artificial intelligence (AI), machine learning, and computer vision to achieve unprecedented levels of accuracy. Equipped with high-resolution sensors and adaptive control algorithms, these robots can detect minute variations in torque, angle, and alignment. This ensures that every screw is fastened to exact specifications, significantly reducing the risk of product defects and failures. The ability to self-correct in real-time means that these systems can maintain optimal performance even in dynamic production environments. Seamless Connectivity and Data Integration A defining characteristic of Industry 4.0 is the interconnectedness of machinery through the Internet of Things (IoT). Modern screw locking robots are designed to be integral nodes within this networked ecosystem. They continuously collect and transmit vital data—such as torque values, fastening times, and error logs—to centralized cloud platforms or edge computing systems. This data is then analyzed to monitor production quality, predict maintenance needs, and optimize overall equipment effectiveness (OEE). For instance, if a robot detects an anomalous torque pattern, it can instantly alert supervisors or trigger adjustments in adjacent machines, preventing costly downtime and ensuring seamless workflow integration. Enhanced Flexibility and Adaptive Manufacturing Today’s manufacturing demands require systems that can quickly adapt to changing product designs and small batch productions. Screw locking robots are becoming increasingly versatile, thanks to advancements in modular design and easy programming interfaces. With the support of collaborative robotics (cobots) and intuitive software, these robots can be rapidly reconfigured to handle different screw types, sizes, and assembly patterns without extensive downtime. This flexibility is crucial for supporting mass customization trends, where production lines must efficiently switch between product variants while maintaining high quality standards. Key Benefits for the Smart Factory Superior Quality Assurance: Consistent and precise fastening eliminates human error, leading to higher product reliability and reduced warranty claims. Increased Productivity: Robots operate continuously at high speeds, drastically reducing cycle times and boosting output. Workplace Safety: By automating repetitive and physically demanding tasks, these robots minimize the risk of worker injuries and ergonomic issues. Data-Driven Insights: The wealth of data generated enables proactive decision-making, predictive maintenance, and continuous process improvement. Looking Ahead: The Road to Autonomous Factories The evolution of screw locking robots is far from over. As AI and IoT technologies mature, we can expect these systems to become even more autonomous and intelligent. Future developments may include fully self-calibrating robots that require zero human intervention, enhanced swarm robotics for coordinated multi-point fastening, and deeper integration with digital twin simulations for virtual testing and optimization. The role of screw locking robots will expand beyond mere assembly to become a cornerstone of the self-organizing, agile, and resilient factories of tomorrow. In conclusion, screw locking robots are poised to play a pivotal role in the ongoing Industry 4.0 revolution. By combining precision engineering with smart connectivity and adaptive capabilities, they are not only improving current manufacturing processes but also paving the way for the fully autonomous smart factories of the future. Embracing these technologies is essential for any organization aiming to thrive in the competitive landscape of modern industrial production. Product Name Applicable industries Screw Fastening Unit Automotive Electronics Assembly

body {font-family: Arial, sans-serif; line-height: 1.6; color: #333;} h1 {color: #1a5276; font-size: 28px;} h2 {color: #2874a6; font-size: 22px; margin-top: 25px;} p {margin-bottom: 16px;} strong {color: #2e86c1;} ul {margin-bottom: 16px; padding-left: 20px;} li {margin-bottom: 8px;} Screw Tightening Solutions for SMEs In the competitive landscape of modern manufacturing, precision, efficiency, and consistency are not just goals—they are necessities for survival and growth. For Small and Medium-sized Enterprises (SMEs), achieving these benchmarks can be particularly challenging due to limited resources and manpower. One critical yet often overlooked aspect of the assembly process is screw tightening. What may seem like a simple task can, in fact, be a significant source of production bottlenecks, quality issues, and costly rework. The Hidden Costs of Manual Screw Tightening Many SMEs still rely on manual screwdrivers operated by line workers. This traditional approach is fraught with inherent risks. Human operators, no matter how skilled, are subject to fatigue, distraction, and variations in technique. This can lead to a range of problems including under-torquing, over-torquing, cross-threading, and even completely forgotten screws. The consequences are severe: product malfunctions, premature wear, safety hazards, and damaged brand reputation. The cost of recalls and warranty claims stemming from these errors can be devastating for a smaller business. Furthermore, manual processes offer no data. Without records of each tightening operation, it is impossible to trace a fault back to a specific step in the assembly or to prove quality control compliance to demanding clients. This lack of traceability is a major disadvantage in industries where documentation is paramount. Embracing Automated Precision The solution lies in embracing automated screw tightening solutions specifically designed for the scale and budget of an SME. These are not the massive, complex robotic cells of high-volume automotive plants; rather, they are agile, programmable, and remarkably affordable tools that integrate seamlessly into existing production lines. Modern electric screwdrivers and automated tightening systems bring a new level of control to the assembly floor. They are programmed to apply exact, predetermined torque and angle values for every single screw. This eliminates guesswork and ensures every joint is consistent and perfect, dramatically reducing the rate of defects. Key Benefits for Your Business Investing in the right screw tightening technology delivers immediate and long-term returns: Uncompromising Quality: Achieve 100% consistency in every product that leaves your line, enhancing reliability and customer satisfaction. Increased Productivity: Automated tools complete tasks faster than manual methods and do not require breaks, significantly boosting output. Comprehensive Traceability: Many systems feature data logging capabilities, creating a digital record for each tightening operation. This provides invaluable data for quality audits, process optimization, and warranty support. Reduced Operational Costs: By virtually eliminating errors and rework, you save on wasted materials, repair labor, and potential warranty claims. It also reduces physical strain on workers, potentially lowering the risk of repetitive strain injuries. Enhanced Flexibility: These systems can be quickly reprogrammed for different torque settings, making them ideal for production lines that handle multiple products. A Smart Investment for Future Growth For an SME, the decision to upgrade assembly processes is a strategic move towards greater competitiveness. Automated screw tightening solutions represent a low-risk, high-reward investment that directly addresses core challenges of quality control and production efficiency. The technology is more accessible than ever, offering a clear path to modernizing your operations without a massive capital expenditure. By leveraging these tools, SMEs can not only improve their bottom line but also build a reputation for quality and reliability that stands out in the market. It’s about working smarter, empowering your workforce with the right technology, and ensuring that every product you build is a testament to precision and excellence. Product Name Applicable industries Dual Head Screwdriver Security Equipment Manufacturing

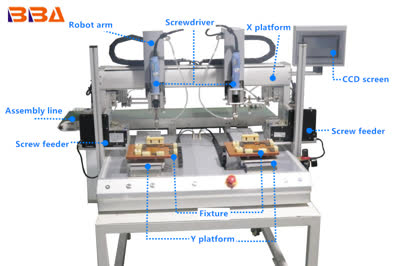

Product Name Applicable industries Dual Head Screwdriver Automotive Electronics Assembly Overview of Floor-Type Screw Locking Machines In the realm of industrial automation, floor-type screw locking machines represent a significant advancement in assembly line technology. These robust systems are engineered to deliver high precision, reliability, and efficiency in fastening applications across various industries, including automotive, electronics, and heavy machinery manufacturing. What is a Floor-Type Screw Locking Machine? A floor-type screw locking machine is a stationary, heavy-duty automated system designed for driving and tightening screws with exceptional accuracy. Unlike benchtop models, these machines are mounted directly onto the factory floor, providing stability for handling larger workpieces or higher torque requirements. They typically incorporate advanced servo motors, precision sensors, and programmable logic controllers (PLCs) to ensure consistent performance. Key components often include a rigid frame, a multi-axis positioning system, automatic screw feeding units, and torque monitoring systems, all integrated to operate seamlessly within automated production environments. Key Features and Advantages These machines offer numerous features that enhance productivity. One standout attribute is their ability to achieve precise torque control, critical for applications where under-tightening or over-tightening could lead to product failure. With programmable settings, operators can easily switch between different screw sizes and tightening specifications, reducing changeover time. The floor-mounted design minimizes vibrations, ensuring accuracy even at high speeds. Additionally, many models come equipped with vision systems or RFID technology to verify correct screw placement and track process data for quality assurance. This level of automation reduces labor costs and human error while increasing throughput. Applications in Modern Manufacturing Floor-type screw locking machines are versatile and can be customized for specific tasks. In the automotive sector, they are used to assemble engine components, chassis parts, and interior fixtures. Electronics manufacturers employ them to secure delicate circuit boards or housing units without damaging sensitive components. The machines' adaptability allows integration into existing assembly lines, working alongside robots or conveyor systems. Their robustness also makes them suitable for industries requiring high torque, such as aerospace or energy, where safety-critical fastening is paramount. Technological Innovations Recent innovations have further elevated the capabilities of these machines. IoT connectivity enables real-time monitoring and predictive maintenance, alerting operators to potential issues before they cause downtime. Advanced algorithms optimize tightening sequences based on historical data, improving consistency. Some systems also incorporate artificial intelligence to self-adjust parameters during operation, compensating for material variations or wear. These smart features contribute to higher overall equipment effectiveness (OEE) and lower total cost of ownership. Conclusion Floor-type screw locking machines are indispensable in today's automated manufacturing landscape. Their precision, durability, and adaptability make them a valuable investment for companies seeking to enhance assembly quality and efficiency. As technology continues to evolve, these machines will likely incorporate even more advanced features, solidifying their role in the future of industrial automation. For businesses looking to streamline their production processes, understanding and leveraging such equipment is key to maintaining a competitive edge.

body { font-family: Arial, sans-serif; line-height: 1.6; color: #333; margin: 20px; } h1 { color: #2c3e50; font-size: 28px; margin-bottom: 20px; } h2 { color: #34495e; font-size: 22px; margin-top: 25px; margin-bottom: 15px; } p { margin-bottom: 15px; } ul { margin-bottom: 15px; padding-left: 20px; } li { margin-bottom: 8px; } .highlight { background-color: #f8f9fa; padding: 15px; border-left: 4px solid #3498db; margin: 20px 0; font-style: italic; } strong { color: #2c3e50; } Reducing Downtime with Multi-Axis Automation In today's competitive industrial landscape, maximizing productivity is paramount. Unplanned equipment downtime remains one of the most significant obstacles to achieving peak efficiency and profitability. It disrupts production schedules, leads to delivery delays, and incurs substantial costs in both repairs and lost output. While traditional automation solutions have made great strides, a new generation of multi-axis automation systems is providing a transformative approach to virtually eliminating these costly interruptions. The High Cost of Unplanned Stoppages Before delving into the solution, it is crucial to understand the true impact of downtime. It is not merely the time a machine is idle. The financial ramifications extend far beyond that. Costs associated with urgent maintenance calls, overtime labor to catch up on lost production, wasted raw materials, and potential penalties for missed deadlines can quickly escalate. Furthermore, unexpected stoppages increase the wear and tear on machinery, as abrupt shutdowns and restarts place additional stress on mechanical and electrical components, potentially leading to more frequent failures in the future. How Multi-Axis Automation Creates Resilience Multi-axis automation refers to sophisticated systems that control movement across several different axes simultaneously. These systems, often powered by advanced controllers and precision servo drives, enable complex, coordinated motions that mimic or even surpass human dexterity. This capability is key to building more resilient and flexible production lines. The core strength of multi-axis systems lies in their integrated intelligence. Unlike a collection of independent single-axis machines, a truly synchronized multi-axis solution is designed from the ground up to work as a cohesive unit. This deep integration offers several distinct advantages for minimizing downtime: Predictive Maintenance Capabilities: Modern multi-axis systems are equipped with extensive sensor networks and diagnostic software that continuously monitor the health of components like motors, drives, and gears. They can detect subtle changes in vibration, temperature, or torque that indicate a potential problem long before it causes a failure. This allows maintenance to be scheduled during planned breaks, preventing unplanned stoppages. Enhanced Flexibility and Rapid Changeover: With their ability to perform complex tasks, a single multi-axis robot can often replace several dedicated machines. This reduces the number of potential failure points on a production line. Furthermore, programming allows for quick and easy changeovers between product lines. This minimizes the downtime associated with reconfiguring equipment for different tasks or products. Superior Precision and Reduced Errors: The high accuracy of multi-axis motion ensures that tasks are performed correctly the first time, every time. This drastically reduces errors, jams, and quality issues that often lead to production halts. Consistent, precise movement also minimizes part-on-part wear, extending the lifespan of both the automation system and the tooling it interacts with. By moving beyond simple repetitive motion to intelligent, coordinated action, multi-axis automation provides a proactive defense against the factors that cause downtime. Building a More Streamlined Operation Implementing a multi-axis automation solution is an investment in the long-term stability and efficiency of your operation. The move towards a fully integrated system simplifies the production floor, replacing complex mechanical linkages with streamlined, software-driven motion. This reduction in mechanical complexity inherently boosts reliability. When a process is controlled by software and a few precision actuators, rather than an intricate series of cams, levers, and relays, there are simply fewer physical components that can break down. The data collected by the system’s diagnostics also provides invaluable insights into your production process. You gain a clear understanding of machine utilization rates, cycle times, and common bottlenecks. This data-driven approach empowers you to make continuous improvements, further optimizing your workflow and preemptively addressing areas that could become future sources of delay. Conclusion: A Strategic Imperative Viewing multi-axis automation solely as a tool for increasing speed is to overlook its most powerful benefit: its role as a critical component for ensuring uninterrupted production. In an era where reliability is directly tied to competitiveness, the ability to predict and prevent downtime is a strategic imperative. By embracing the intelligence, flexibility, and precision of multi-axis systems, manufacturers can not only enhance their productivity but also build a foundation for a more predictable, efficient, and profitable future. Product Name Applicable industries Desktop Screwdriver Robot Telecommunication Equipment Assembly

When it comes to screw tightening equipment for industrial automation, manufacturers often face a critical decision: should they opt for off-the-shelf OEM (Original Equipment Manufacturer) solutions or invest in custom-built systems? Both approaches have their merits, and the right choice depends on factors such as production requirements, budget, scalability, and long-term operational goals. Understanding the differences between OEM and custom-built screw tightening equipment can help businesses make an informed decision that aligns with their unique needs. OEM screw tightening equipment refers to standardized, pre-designed systems that are mass-produced and readily available for purchase. These systems are typically designed to handle common applications and are built with versatility in mind. They are often more affordable upfront and can be deployed quickly, reducing lead times. OEM solutions are ideal for companies with standard assembly processes or those operating in industries where screw tightening requirements are consistent and well-defined. However, the downside is that these systems may lack the flexibility to adapt to highly specialized or evolving production needs. On the other hand, custom-built screw tightening equipment is tailored to specific operational requirements. These systems are designed from the ground up to address unique challenges, such as unusual workpiece geometries, stringent torque accuracy demands, or integration with existing automation infrastructure. Custom solutions offer greater precision, efficiency, and scalability, making them suitable for high-volume production environments or industries with complex assembly processes. While the initial investment and development time may be higher, the long-term benefits—including improved productivity, reduced error rates, and lower total cost of ownership—often justify the expense. One of the key advantages of custom-built equipment is the ability to incorporate advanced features such as real-time data monitoring, adaptive torque control, and seamless integration with IoT platforms. These capabilities enable predictive maintenance, quality assurance, and continuous process optimization, which are increasingly important in smart manufacturing environments. OEM solutions may offer some of these features as add-ons, but they are generally less optimized for specific use cases. Ultimately, the decision between OEM and custom-built screw tightening equipment hinges on a careful evaluation of current and future needs. Companies with standardized processes and limited budgets may find OEM solutions to be a practical choice. In contrast, those with complex requirements, a focus on innovation, and a need for seamless integration may benefit more from a custom-built approach. Regardless of the choice, partnering with a reliable provider ensures that the equipment meets quality standards and delivers consistent performance. As industrial automation continues to evolve, the demand for smarter, more adaptable screw tightening solutions will only grow. By weighing the pros and cons of OEM and custom-built options, businesses can select the right technology to enhance their assembly operations, improve product quality, and maintain a competitive edge in the market. Product Name Applicable industries Smart Screw Driving Machine Automotive Electronics Assembly

Product Name Applicable industries Screw Fastening Unit Automotive Electronics Assembly How to Troubleshoot a Jammed Screw Feeder Screw feeders are critical components in many industrial automation systems, designed to handle precise and consistent delivery of screws or similar fasteners. However, like any mechanical device, they can experience jams that disrupt production flow. Troubleshooting a jammed screw feeder requires a systematic approach to identify and resolve the issue efficiently. This guide provides practical steps to diagnose and fix common problems, ensuring minimal downtime and maintaining productivity. First, ensure the feeder is powered off and disconnected from any energy sources before starting any inspection or maintenance. Safety should always be the top priority. Begin by visually inspecting the feeder bowl and track. Look for obvious obstructions such as foreign objects, damaged screws, or accumulated debris. Even small particles can cause jams, so clean the bowl and track thoroughly using appropriate tools like brushes or compressed air. Avoid using sharp objects that might scratch or damage the surfaces, as this could lead to future issues. Next, check the screw specifications. Using incorrect screw sizes, types, or those with defects like burrs or misformed heads can frequently cause jams. Verify that the screws meet the recommended specifications for your feeder model. If the screws are correct, examine the feeder's alignment and mounting. Vibrations or misalignment can disrupt the feeding process, so ensure all components are securely fastened and level. Adjust the feeder's settings, such as vibration intensity or feed rate, as per the manufacturer's guidelines. Overly aggressive settings might cause screws to jump or pile up, leading to jams. If the problem persists, inspect internal components like the drive mechanism or spring coil for wear and tear. Worn parts may not function optimally, requiring replacement. Regular preventive maintenance, including lubrication and part inspections, can prevent many jams. For persistent or complex issues, consult the product manual or seek support from technical experts. By following these steps, you can quickly restore your screw feeder's operation and enhance system reliability. In summary, troubleshooting a jammed screw feeder involves a combination of cleaning, verification of materials, mechanical adjustments, and preventive care. Addressing these factors methodically will help maintain efficient and uninterrupted automation processes, supporting overall operational excellence.

Product Name Applicable industries Screw Locking Robot Smartphone Manufacturing body { font-family: Arial, sans-serif; line-height: 1.6; color: #333; } h1 { color: #2c3e50; } h2 { color: #34495e; margin-top: 1.5em; } p { margin-bottom: 1em; } ul { margin-bottom: 1em; } li { margin-bottom: 0.5em; } strong { font-weight: bold; } .code { font-family: monospace; background-color: #f4f4f4; padding: 5px; border-radius: 3px; } .note { background-color: #ffffcc; padding: 10px; border-left: 4px solid #ffeb3b; } How to Set Up a Multi-Axis Screw Tightening System Implementing a multi-axis screw tightening system is a significant step forward for any manufacturing line focused on precision, efficiency, and reliability. These sophisticated systems can handle multiple fastening points simultaneously or in rapid sequence, drastically reducing cycle times and eliminating human error. Setting up such a system, however, requires careful planning and execution. This guide outlines the key steps involved in deploying a successful multi-axis tightening solution. 1. Pre-Installation Planning and Design Thorough planning is the most critical phase of the setup process. Rushing this stage can lead to costly delays and subpar performance later. Define Application Requirements: Clearly identify the product(s) to be assembled. Determine the number of screws, their locations, torque and angle specifications, and the required sequence for each joint. Select the Right System: Choose a system with the appropriate number of spindles and the necessary reach to access all fastening points on your workpiece. Consider whether a simultaneous tightening (all spindles at once) or a sequential approach is best for your product's structure and accuracy needs. Workholding and Fixturing: Design a robust fixture that securely holds the product in place during the violent forces of simultaneous tightening. The fixture must prevent flexing or misalignment, which can lead to inaccurate torque readings and product damage. Integration Strategy: Plan how the system will integrate with your existing production line. This includes mechanical integration (conveyors, lifts), electrical connections (PLC I/O, safety circuits), and data communication (MES/ERP systems) for traceability. 2. Mechanical and Electrical Installation With a solid plan in place, the physical installation can begin. Foundation and Mounting: Ensure the system is mounted on a stable, level surface capable of handling its weight and the reactive forces generated during operation. Spindle Alignment: Precisely align each spindle to its corresponding screw hole. Misalignment is a primary cause of cross-threading, which damages both the product and the screwdriver bits. Use laser alignment tools for the highest accuracy. Power and Air Supply: Provide clean, stable electrical power and compressed air according to the manufacturer's specifications. Voltage fluctuations or dirty air can severely impact performance and equipment lifespan. Safety Circuitry: Integrate all necessary safety components, such as light curtains, area scanners, or emergency stop buttons, into the machine's safety circuit. This is non-negotiable for operator protection. 3. System Configuration and Programming This is where the system is taught how to perform its task. Controller Setup: Program the system's controller with the tightening parameters for each spindle: target torque, torque window, target angle, and acceptable tolerances. For complex joints, angle-controlled tightening is often more accurate than pure torque control. Sequence Programming: Define the order in which spindles will operate if not simultaneous. This is crucial for minimizing part distortion. Data Logging Setup: Configure the system to collect and store data from every tightening operation. Each record should include a timestamp, spindle ID, actual torque, final angle, and a pass/fail status. This data is essential for full traceability and quality assurance. IO Configuration: Map the digital inputs and outputs to communicate seamlessly with the line PLC. For example, an output signal indicating "Tightening Cycle Complete" or an input to "Start Next Cycle." 4. Calibration, Testing, and Validation Before going live, the system must be rigorously tested. Calibration: Ensure all torque transducers are calibrated according to a traceable standard. The frequency of calibration should be defined based on usage and criticality. Dry-Run Testing: Run the system without a product to verify spindle sequencing, movement, and communication signals. Process Validation: Run multiple cycles with sample products. Use a calibrated torque analyzer to verify that the system is applying the correct torque and angle to each joint. Analyze the data logs to ensure consistency and repeatability. Cycle Time Analysis: Confirm that the system meets the required cycle time for your production line. 5. Operator Training and Ongoing Maintenance A well-set-up system is only effective if the team knows how to use and maintain it. Comprehensive Training: Train operators on how to start, stop, and monitor the system. Train maintenance personnel on basic troubleshooting, bit changes, and preventive maintenance tasks like lubrication. Preventive Maintenance Schedule: Establish a strict schedule for checking and maintaining mechanical components (spindle bearings, gears) and recalibrating torque sensors. A successful multi-axis screw tightening system setup hinges on meticulous planning, precise installation, and thorough validation. By following these steps, you can unlock new levels of speed, quality, and data-driven insight in your assembly process, ensuring every product is built perfectly, every time.