8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

body { font-family: Arial, sans-serif; line-height: 1.6; color: #333; margin: 20px; } h1 { color: #0056b3; font-size: 28px; margin-bottom: 20px; } h2 { color: #004494; font-size: 22px; margin-top: 25px; margin-bottom: 15px; } p { margin-bottom: 15px; text-align: justify; } strong { color: #0056b3; } ul { margin-bottom: 15px; padding-left: 20px; } li { margin-bottom: 8px; } Flexible Programming for Product Changeovers In today's fast-paced industrial landscape, the ability to adapt quickly to market demands is a critical competitive advantage. For manufacturing facilities, this often means frequent product changeovers on production lines. Traditional automation systems, with their rigid and fixed programming, can become a significant bottleneck in this process. They often require extensive manual intervention, lengthy downtime, and specialized programming expertise to reconfigure for a new product run. This is where the power of flexible programming truly shines, transforming changeovers from a costly necessity into a seamless, efficient operation. What is Flexible Programming? Flexible programming in industrial automation refers to the design and implementation of software that is inherently adaptable. Instead of hard-coding every parameter for a specific product, a flexible system uses a more abstract and data-driven approach. Key operational parameters—such as dimensions, weights, speeds, and assembly sequences—are stored externally in recipe files or databases. The core control program remains constant, but it dynamically reads the required parameters from these files at the start of a production run. This fundamental shift eliminates the need to modify the core logic for every single product variant. Key Benefits for Manufacturing Operations Adopting a flexible programming strategy offers a multitude of tangible benefits that directly impact the bottom line. Drastically Reduced Changeover Time: Switching from one product to another becomes a matter of selecting a new recipe and initiating the cycle. This can reduce changeover time from hours to minutes, maximizing machine uptime and overall equipment effectiveness (OEE). Enhanced Operational Agility: Responding to custom orders or introducing new products is significantly faster. There is no longer a need to halt production for lengthy reprogramming, allowing you to meet shifting customer demands with ease. Reduced Dependency on Specialized Skills: Changeovers can be managed by line operators rather than highly trained control engineers. The intuitive interface, often an HMI panel, guides the operator through the simple selection process, minimizing the potential for human error. Improved Consistency and Quality: Automated recipe management ensures that every time a product is run, the exact same parameters are applied. This eliminates the variability introduced by manual adjustments, leading to consistently high product quality. Future-Proofing Your Investment: A flexible control system is designed to accommodate growth. Adding a future product variant is as simple as creating a new recipe profile, protecting your automation investment for years to come. Implementing a Flexible Approach Transitioning to a flexible programming model requires a strategic approach. It begins at the design phase of the automation system. Engineers must architect the control code with modularity and data-driven principles in mind. Standardized templates for machine modules (e.g., a conveyor section, a robot cell, a vision station) can be created, each configurable via external parameters. The use of structured variables and array indexing is crucial. Furthermore, a user-friendly Human-Machine Interface (HMI) is essential. This interface serves as the gateway for operators, providing them with clear dropdown menus, recipe selection screens, and straightforward commands to load and execute new parameters safely and efficiently. In conclusion, the move towards flexible programming is no longer a luxury but a necessity for modern manufacturing. It is a powerful strategy that empowers manufacturers to achieve new levels of agility, efficiency, and quality. By decoupling control logic from product-specific parameters, companies can turn the challenge of frequent changeovers into a streamlined, competitive strength, ensuring they are well-equipped to thrive in a dynamic market. Product Name Applicable industries Servo Screwdriver Robot Smartphone Manufacturing

body { font-family: Arial, sans-serif; line-height: 1.6; color: #333; margin: 20px; } h1 { color: #0056b3; font-size: 28px; margin-bottom: 20px; } h2 { color: #003366; font-size: 22px; margin-top: 25px; margin-bottom: 15px; } p { margin-bottom: 15px; text-align: justify; } ul { margin-bottom: 15px; padding-left: 20px; } li { margin-bottom: 8px; } .highlight { background-color: #f0f8ff; padding: 15px; border-radius: 5px; margin: 20px 0; } Anti-Cross Threading Features in Advanced Fasteners In the demanding world of industrial automation, the integrity of every connection is paramount. A single failed fastener can lead to system downtime, reduced product quality, and significant maintenance costs. One of the most common and frustrating issues encountered during assembly is cross-threading. This occurs when the threads of a screw and nut are misaligned during engagement, causing them to cut across each other instead of mating correctly. The result is a damaged thread, a weakened connection, and a potential point of failure. To combat this, advanced fasteners are now being engineered with sophisticated anti-cross threading features, representing a significant leap forward in assembly reliability and efficiency. Understanding the Problem: The Cost of Cross-Threading Cross-threading is often a result of human error or misalignment in automated equipment. Even with precise robotics, angular misalignment can occur. The consequences are immediate and severe. The incorrectly mated threads gall and strip, compromising the fastener's clamping force and vibration resistance. This damaged connection must be reworked, requiring additional labor time and often replacing expensive components. In critical applications, such as within robotic arms or precision conveyor systems, a cross-threaded fastener can lead to catastrophic mechanical failure, unplanned production stops, and safety hazards. The pursuit of error-proof assembly has made eliminating this issue a top priority for engineers. Innovative Engineering Solutions Modern fastener design has moved beyond basic thread forms to incorporate intelligent features that prevent misalignment. These are not mere gimmicks but are the product of precise engineering and deep understanding of assembly dynamics. Key technologies include: Lead-In Threads with Chamfered Profiles: Fasteners are designed with a pronounced and highly tapered lead-in thread. This large chamfer acts as a funnel, guiding the screw into the nut or tapped hole even when presented at a slight angle. It allows for a greater margin of error during the initial engagement phase, automatically correcting minor misalignments before the full threads make contact. Self-Centering Designs: Some advanced nuts and bolt heads feature a spherical or radiused seating surface. This design allows the fastener to pivot slightly within its seat, automatically finding the correct centerline alignment as torque is applied. This is particularly valuable in applications where hole tolerances may vary. Asymmetric and Specialized Thread Forms: Research into unique thread geometries that are more resistant to off-angle engagement is ongoing. These designs can make it physically difficult for the screw to begin cutting a new path, effectively channeling it into the proper mating thread. The core principle behind these features is to make the correct assembly path the path of least resistance. By guiding components into perfect alignment, these fasteners ensure a true, square engagement every time. Tangible Benefits for Automated Production The integration of anti-cross threading features delivers measurable advantages across the manufacturing process. Firstly, it dramatically increases assembly speed. Automated drivers and robotic arms can operate with higher confidence and less need for complex vision systems to achieve perfect alignment, reducing cycle times. Secondly, it drastically improves first-pass yield and reduces scrap and rework. The cost associated with replacing damaged threads in critical components is eliminated. Most importantly, it enhances the overall quality and reliability of the final product. Every connection achieves its intended clamp load and performs predictably under stress and vibration, ensuring the long-term operational integrity of the automated machinery. As automation continues to evolve towards lights-out factories and increasingly complex assemblies, the demand for such mistake-proof components will only grow. Anti-cross threading features are no longer a luxury but a necessity for anyone seeking to maximize uptime, ensure quality, and reduce the total cost of production. This innovation in fastener technology is a quiet but powerful revolution driving reliability forward on the factory floor. Product Name Applicable industries Auto Screwdriver Machine Medical Device Manufacturing

Product Name Applicable industries Servo Screwdriver Robot Electric Bicycle Assembly In the world of industrial automation, screw feeders are indispensable components used across various sectors such as food processing, pharmaceuticals, chemicals, and manufacturing. These devices ensure precise and consistent delivery of materials, which is critical for maintaining production efficiency and product quality. However, like any mechanical system, screw feeders are subject to wear and tear, and unplanned downtime can result in significant production losses. To minimize disruptions and extend the lifespan of your equipment, it is essential to keep a well-stocked inventory of spare parts. This article highlights the most important spare parts to have on hand for screw feeders. One of the most critical components to keep in stock is the screw auger or conveyor screw. This part is responsible for moving materials through the feeder and is prone to wear, especially when handling abrasive or corrosive substances. Over time, the flighting may wear down, leading to reduced efficiency and accuracy. Having a replacement auger readily available can drastically reduce downtime when wear becomes significant. Another vital spare part is the drive motor. The motor is the heart of the screw feeder, providing the necessary power to rotate the auger. Motors can fail due to electrical issues, overheating, or general wear. Keeping a compatible motor in storage ensures that you can quickly replace a faulty unit and resume operations without waiting for procurement and delivery. Gearboxes are also essential spares. They transmit power from the motor to the auger and can suffer from lubrication failures, bearing wear, or gear damage. A malfunctioning gearbox can bring the entire system to a halt. By having a spare gearbox, you can swiftly address these issues and avoid prolonged production interruptions. Bearings are small but crucial components that support the rotating auger shaft. They are susceptible to contamination, misalignment, and fatigue. Failed bearings can cause excessive vibration, noise, and even damage to other parts. It is advisable to keep a set of high-quality bearings suitable for your specific screw feeder model to facilitate quick replacements. The liner or tube in which the auger rotates is another part that experiences significant wear. In many designs, this liner is designed to be replaceable. Abrasive materials can wear down the inner surface, leading to increased clearance between the auger and the liner, which affects feeding accuracy. A spare liner can be installed during scheduled maintenance to restore optimal performance. Couplings connect the motor to the gearbox or the gearbox to the auger shaft. These components can wear out or fail due to misalignment or torque overload. Having spare couplings on hand ensures that you can quickly reconnect the drive train without delays. Seals and gaskets are important for preventing material leakage and contamination. In food and pharmaceutical applications, maintaining hygiene is paramount. Worn seals can lead to product loss and safety issues. A stock of appropriate seals and gaskets allows for prompt maintenance, ensuring compliance with industry standards. Lastly, electrical components such as sensors, controllers, and wiring harnesses should be considered. Modern screw feeders often include advanced control systems for precise operation. Faulty sensors or electrical connections can disrupt the entire feeding process. Keeping critical electronic spares can help in quickly troubleshooting and resolving electrical problems. In conclusion, maintaining a strategic inventory of spare parts for screw feeders is a proactive approach to ensuring continuous and efficient operation. By prioritizing components such as augers, motors, gearboxes, bearings, liners, couplings, seals, and electrical parts, you can significantly reduce downtime, enhance productivity, and protect your investment in automation technology. Regular maintenance, combined with ready access to these spares, will keep your systems running smoothly and reliably.

body {font-family: Arial, sans-serif; line-height: 1.6; color: #333; margin: 20px;} h1 {color: #2c3e50; font-size: 28px; border-bottom: 2px solid #3498db; padding-bottom: 10px;} h2 {color: #16a085; font-size: 22px; margin-top: 25px;} p {margin-bottom: 15px; text-align: justify;} strong {color: #e74c3c;} ul {margin-left: 20px; margin-bottom: 20px;} li {margin-bottom: 8px;} Error Detection Capabilities in Automatic Screw Machines In the high-stakes world of industrial manufacturing, precision and reliability are non-negotiable. Automatic screw machines have long been the backbone of high-volume production lines for intricate parts. While their speed and efficiency are unparalleled, the true advancement in modern systems lies in their sophisticated error detection capabilities. These integrated systems are critical for minimizing waste, reducing downtime, and ensuring consistently high product quality. The Critical Need for Error Detection Traditional automated assembly could proceed for minutes or even hours before a simple error—a cross-threaded screw, a missing component, or a stripped head—was discovered. By that time, an entire batch of products could be rendered defective, leading to significant material waste and costly rework. Modern automatic screw machines are equipped with a multi-layered defense against such errors, transforming them from simple fastening tools into intelligent data hubs on the production floor. Key Error Detection Technologies Contemporary automatic screw machines employ a suite of sensors and software algorithms to monitor the fastening process in real-time. The primary detection methods include: Torque and Angle Monitoring: This is the most fundamental and crucial capability. The system charts the torque and rotation angle throughout the entire driving cycle. By comparing this real-time curve against a predefined "golden" profile, the machine can instantly identify abnormalities. A spike in torque might indicate a cross-thread, while a lower-than-expected torque could signal a stripped screw or a missing hole. Vision System Integration: Advanced systems are often equipped with integrated cameras. These vision systems perform critical pre-and post-drive checks. They can verify the presence of a screw on the driver bit before the operation begins and inspect the final assembly to ensure the screw is seated correctly and flush, preventing proud screws or damaged surfaces. Screw Presence Detection: Using sensors, either mechanical, optical, or pneumatic, the machine confirms that a screw has been successfully picked up from the feeder bowl. This prevents the machine from attempting a drive cycle without a screw, which would result in a missed assembly and potential damage to the product or tooling. Depth and Height Sensing: Laser or ultrasonic sensors measure the height of the screw head after driving. This ensures the screw has been driven to the correct depth—neither too loose nor too tight—which is vital for the structural integrity and safety of the final product. Beyond Detection: Response and Data Analytics The true power of these systems is not just in finding errors but in their immediate response. Upon detecting a fault, the machine can be programmed to automatically stop the production line, trigger an audible and visual alarm for an operator, and even mark the defective unit for rejection. Furthermore, all error data is logged. This creates a valuable historical record for analytics, allowing manufacturers to identify recurring issues, perform root cause analysis, and implement proactive process improvements, thereby moving towards a zero-defect manufacturing environment. Conclusion The integration of advanced error detection capabilities has fundamentally elevated the role of the automatic screw machine. It is no longer just a tool for assembly but a guardian of quality. By providing real-time monitoring, instant feedback, and valuable production data, these systems ensure that manufacturers can achieve new heights of efficiency, reduce costs, and most importantly, guarantee the reliability and quality of every product that leaves their facility. Investing in such intelligent automation is no longer an option but a necessity for any operation serious about competitiveness and excellence in modern manufacturing. Product Name Applicable industries Dual Head Screwdriver Power Tool Assembly Lines

Product Name Applicable industries Screw Locking Robot Security Equipment Manufacturing body { font-family: Arial, sans-serif; line-height: 1.6; margin: 20px; } h1 { color: #2c3e50; font-size: 28px; } h2 { color: #34495e; font-size: 22px; margin-top: 25px; } p { margin-bottom: 15px; color: #333; } strong { color: #16a085; } ul { margin-top: 10px; margin-bottom: 15px; padding-left: 20px; } li { margin-bottom: 8px; } Replacing Worn Screwdriver Bits Safely In the fast-paced environment of industrial automation, every component plays a critical role in maintaining seamless operations. Among these, screwdriver bits are fundamental yet often overlooked. These small tools endure significant stress and wear over time, and their failure can lead to costly downtime, product defects, or even safety hazards. Ensuring their safe and timely replacement is not just a maintenance task—it's a crucial aspect of operational excellence and workplace safety. Why Safe Replacement Matters A worn screwdriver bit is more than just an inefficient tool; it's a liability. Signs of wear include stripped heads, rounded edges, reduced torque transmission, and visible damage. Using a compromised bit can result in several risks: Product Quality Issues: A worn bit cannot apply consistent torque, leading to improperly fastened assemblies. This can cause product malfunctions, recalls, or failures in the field. Equipment Damage: Slipping or misaligned bits can damage the screw head, the workpiece, and even the automated screwdriving unit itself, leading to expensive repairs. Worker Safety Hazards: The most significant concern is operator safety. A worn bit can slip unexpectedly, ejecting metal shards or causing sudden jerks in machinery. In high-speed automation cells, this poses a risk of injury to personnel nearby. Increased Downtime: Frequent failures necessitate unplanned stoppages, disrupting production schedules and reducing overall equipment effectiveness (OEE). Proactive replacement is therefore essential for maintaining a safe, efficient, and reliable production line. Best Practices for Safe Replacement Adopting a structured approach to replacing worn bits minimizes risk and maximizes productivity. Here are key steps to integrate into your maintenance protocol: 1. Establish a Regular Inspection Schedule: Implement a preventive maintenance routine to check bits for wear. The frequency of checks should be based on usage intensity and the manufacturer's guidelines. Look for signs of deformation, corrosion, or loss of magnetic strength. 2. Use the Correct Tools: Always power down and lock out the automated screwdriving system before attempting any replacement. This ensures zero energy flow and prevents accidental activation. Use designated tools, such as precision hex keys, that are designed for your specific equipment to avoid damaging the tool holder. 3. Select High-Quality Replacement Bits: Not all bits are created equal. Invest in bits made from high-grade materials, such as S2 alloy steel, with proper hardening and coatings. Quality bits last longer, maintain torque accuracy, and reduce the frequency of changes, enhancing safety and efficiency. 4. Follow Proper Installation Procedures: Ensure the new bit is securely seated in the collet or magnetic holder. A loose bit can lead to inaccuracies and vibrations that accelerate wear. Refer to the machine’s manual for the recommended installation method and torque specifications if applicable. 5. Train Personnel Thoroughly: Operators and maintenance staff should be trained not only on how to change bits but also on how to identify wear patterns and understand the importance of the procedure. Emphasize the safety protocols, including the use of personal protective equipment (PPE) like safety glasses and gloves during replacement. 6. Document and Track Usage: Maintain a log of bit usage and replacement history. Tracking the lifespan of bits helps in predicting failures and optimizing the inventory of spare parts, ensuring they are always available when needed. Conclusion In industrial automation, attention to detail separates good operations from great ones. The safe replacement of worn screwdriver bits is a small but vital detail that protects your personnel, your product quality, and your productivity. By implementing a rigorous, safety-focused maintenance routine, you invest in the longevity of your equipment and the well-being of your team. Remember, in a world driven by precision, there is no room for worn-out tools.

body { font-family: Arial, sans-serif; line-height: 1.6; color: #333; max-width: 800px; margin: 0 auto; padding: 20px; } h1 { color: #2c3e50; font-size: 24px; margin-bottom: 20px; } h2 { color: #34495e; font-size: 20px; margin-top: 30px; margin-bottom: 15px; } p { margin-bottom: 15px; } ul, ol { margin-bottom: 15px; padding-left: 20px; } strong { font-weight: bold; } Understanding Torque Settings and Applications In the world of industrial automation, torque settings play a critical role in ensuring the efficiency, safety, and longevity of mechanical systems. Proper torque application is essential for maintaining the integrity of fasteners, preventing equipment failure, and optimizing performance. This article explores the fundamentals of torque settings and their practical applications in industrial automation. The Importance of Torque Control Torque, the rotational force applied to a fastener, must be carefully controlled to achieve optimal results. Insufficient torque can lead to loose connections, while excessive torque may cause damage to components or threads. Some key reasons for proper torque control include: Ensuring consistent clamping force for secure connections Preventing damage to sensitive components Maintaining uniform performance across production lines Reducing maintenance costs and downtime Factors Affecting Torque Requirements Several variables influence the appropriate torque settings for different applications: Material properties: The composition of both the fastener and the joined materials Surface conditions: Lubrication, coatings, or surface treatments present Thread type and size: Metric vs. imperial, fine vs. coarse threads Environmental conditions: Temperature, humidity, and potential corrosion factors Types of Torque Applications In industrial automation, torque control is applied in various scenarios: Assembly processes: Precise fastening of mechanical components Maintenance operations: Consistent tightening during equipment servicing Quality control: Verification of proper torque in finished products Robotic applications: Automated torque control in manufacturing cells Best Practices for Torque Management To achieve reliable results in torque-sensitive applications, consider these best practices: Use calibrated torque tools regularly maintained and verified Follow manufacturer specifications for each application Consider using torque auditing systems for critical connections Train personnel on proper torque techniques and procedures Document torque settings and procedures for consistency Understanding and properly applying torque settings is fundamental to the success of industrial automation operations. By implementing appropriate torque control measures, manufacturers can improve product quality, enhance safety, and reduce costly equipment failures. As automation continues to evolve, precise torque management remains a cornerstone of efficient and reliable industrial processes. Product Name Applicable industries Inline Screw Locking System Drone and UAV Manufacturing

Product Name Applicable industries Smart Screw Driving Machine Electric Bicycle Assembly Desktop robots have become essential tools in modern manufacturing, offering precision and efficiency in assembly processes. A key component in these robots is the screw feeding system, which ensures smooth operation. However, issues with screw feeding can disrupt production, leading to downtime and reduced productivity. This article explores common screw feeding problems in desktop robots and provides practical diagnostic steps to address them. Common Screw Feeding Issues Screw feeding systems in desktop robots can encounter several performance-affecting problems. Some of the most frequent issues include: Jamming: Screws may get stuck in the feeder due to misalignment, debris, or incorrect screw size. Irregular Feeding: Screws may not be delivered consistently, causing assembly process gaps. Misfeeds: The system may pick up multiple screws or none at all, leading to errors. Wear and Tear: Components like feeder tracks or nozzles may degrade over time, reducing efficiency. Diagnosing Screw Feeding Problems To identify and resolve screw feeding issues, follow these diagnostic steps: Inspect the Feeder Mechanism: Check for physical obstructions, misaligned tracks, or worn parts that could cause jamming or misfeeds. Verify Screw Specifications: Ensure the screws match the feeder’s design in size, shape, and material. Clean the System: Dust, oil, or debris accumulation can cause irregular feeding. Regular cleaning maintains smooth operation. Test the Sensor: Faulty sensors may fail to detect screws. Verify sensor alignment and functionality. Monitor Vibration and Air Pressure: Improper settings in vibration or pneumatic mechanisms can disrupt feeding. Adjust as needed. Preventive Maintenance Tips To minimize screw feeding issues, adopt these preventive measures: Schedule regular feeder assembly inspections and maintenance. Use high-quality screws meeting the robot’s specifications. Keep the workspace clean to prevent contamination. Train operators to recognize early signs of feeding problems. Understanding these common issues and implementing proactive solutions helps manufacturers ensure reliable desktop robot performance in industrial automation. Proper diagnosis and maintenance of screw feeding systems are key to optimizing productivity and minimizing downtime.

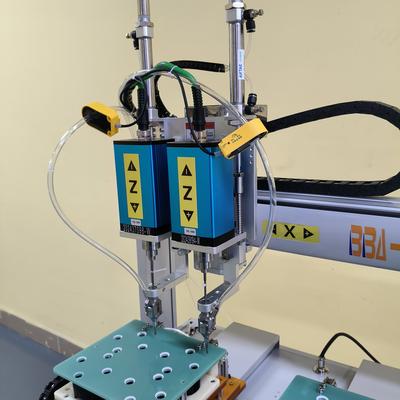

In the fast-paced world of industrial manufacturing, precision, efficiency, and reliability are paramount. Multi-axis screw tightening machines have emerged as a game-changer, offering unmatched performance for assembly lines. These advanced machines streamline production, reduce errors, and enhance consistency across a wide range of applications. Let’s explore the key features that make multi-axis screw tightening machines indispensable in modern automation. High Throughput with Multiple Spindles The primary advantage of multi-axis screw tightening machines is their ability to handle multiple fastening points simultaneously. Equipped with several spindles, these machines can tighten multiple screws in a single cycle, drastically reducing assembly time. Whether it's a complex automotive component or a consumer electronics device, the multi-spindle design ensures high throughput without compromising precision. Precision Torque Control Consistent and accurate torque application is critical to prevent product defects and ensure long-term reliability. Multi-axis screw tightening machines incorporate advanced torque control systems, often with real-time monitoring and feedback mechanisms. This guarantees that each screw is tightened to the exact specification, eliminating over-tightening or under-tightening—common causes of product failures. Flexible Configurations One of the standout features of these machines is their adaptability. Depending on the production requirements, the number of spindles and their arrangement can be customized. Some models feature programmable axis positions, allowing dynamic adjustments to accommodate different workpiece geometries. This flexibility makes them suitable for high-mix, low-volume production environments. Automation and Integration Designed for seamless integration into automated production lines, multi-axis screw tightening machines often come with robotic compatibility and PLC (Programmable Logic Controller) interfaces. They can synchronize with conveyors, part feeders, and inspection systems, creating a fully automated assembly process. This minimizes manual intervention, reduces labor costs, and increases overall efficiency. User-Friendly Operation Despite their complexity, modern multi-axis screw tightening machines feature intuitive interfaces. Touchscreen controls and graphical programming simplify setup, while diagnostic tools provide real-time alerts for maintenance or calibration needs. Operators can quickly switch between different product configurations without extensive downtime. Robust Construction Built for demanding industrial environments, these machines are constructed with high-quality materials such as hardened steel and reinforced aluminum. They are designed to withstand continuous operation, vibrations, and harsh conditions, ensuring long service life with minimal maintenance. Conclusion Multi-axis screw tightening machines represent the pinnacle of modern automation, combining speed, precision, and adaptability. By integrating these advanced systems into production lines, manufacturers can achieve unparalleled efficiency, reduce defects, and maintain consistent quality across their products. As industries continue to evolve, the demand for smarter and more versatile tightening solutions will only grow, solidifying the role of multi-axis machines in the future of industrial assembly. Product Name Applicable industries Auto Screwdriver Machine Laptop and Tablet Assembly