8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

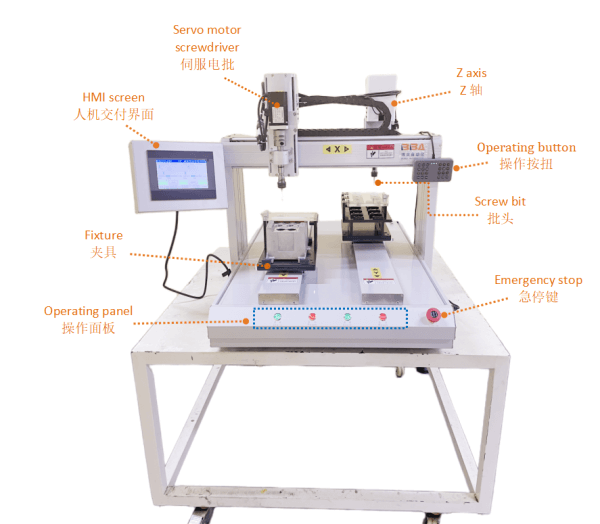

| Voltage | AC110/220V 50/60HZ |

| Power | 1000W |

| Stroke | 500*400*400*100mm (X*Y*Z), can be customized |

| Movement speed | 10-500mm/S |

| Position accuracy | ±0.05mm/axis |

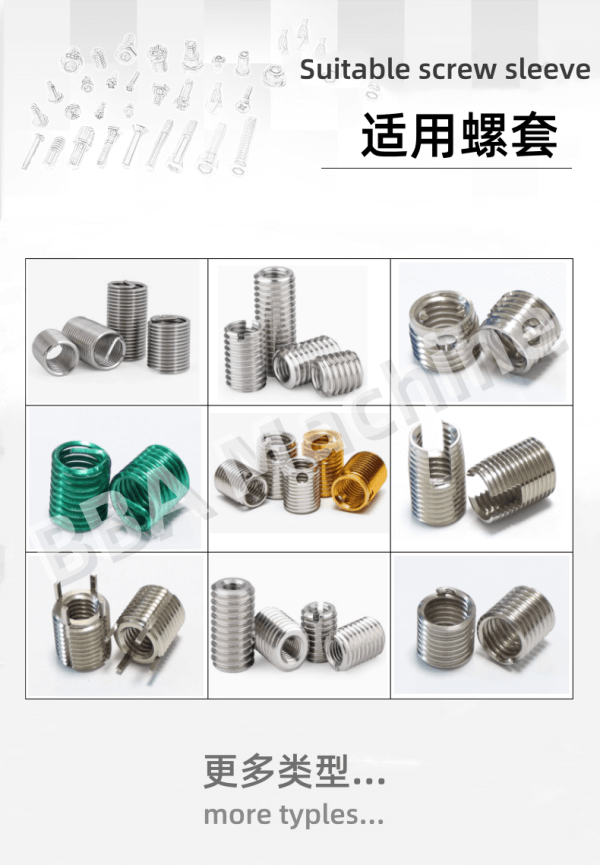

| Universal screw thread | M3-M10 |

| Screw thread height | 6-20mm |

| Screw thread material | Copper, Aluminum, Metal, Stainless steel |

| Screw thread type | Self-tapping thread, screw thread, steel thread |

| Transmission mode | Precision toothed belt+guide rail |

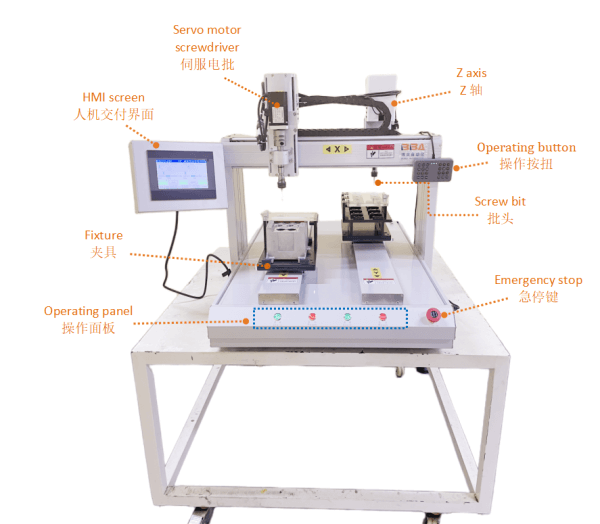

| Control panel | PLC+HMI screen |

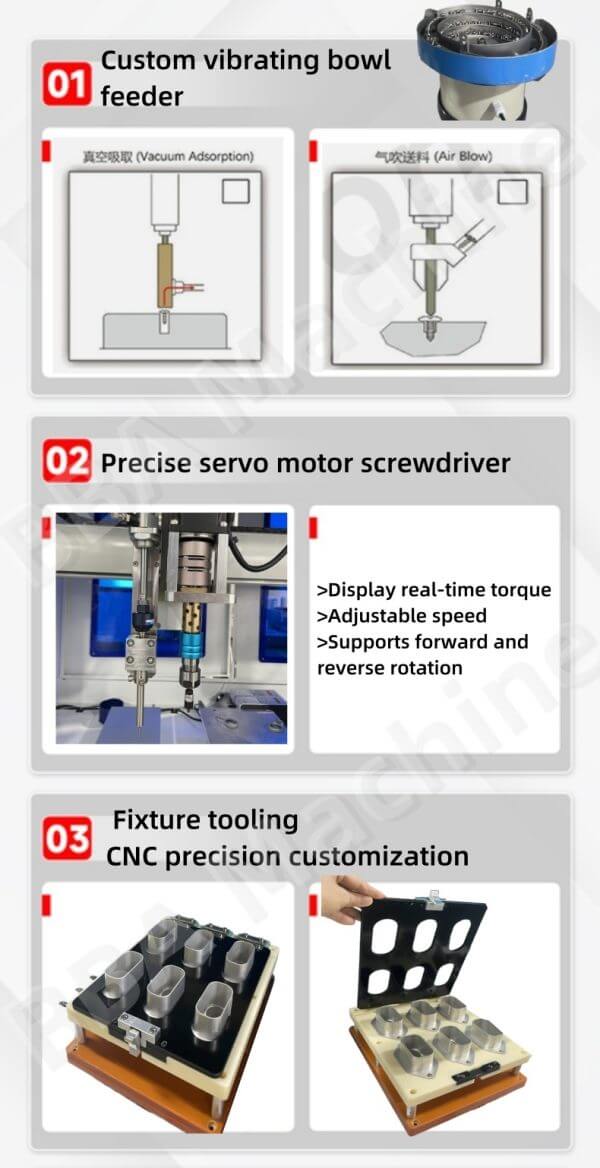

| Conveying mode | Vibrating plate+direct vibrating track |

| Work efficiency | 6S/pcs (include cutting thread tail), details depends on thread size |

| Air pressure | 0.4-0.6Mpa |

| External port | RS232 |

| Program capacity | 12 groups, 20 points per group; can be customized |

| Work environment | Temperature: 5-40℃ Humidity: 20-90% |

| Weight | 580kg(Subject to the actual product) |

| External machine size (L*W*H) | 1150*1350*1650 mm(Can be customized) |

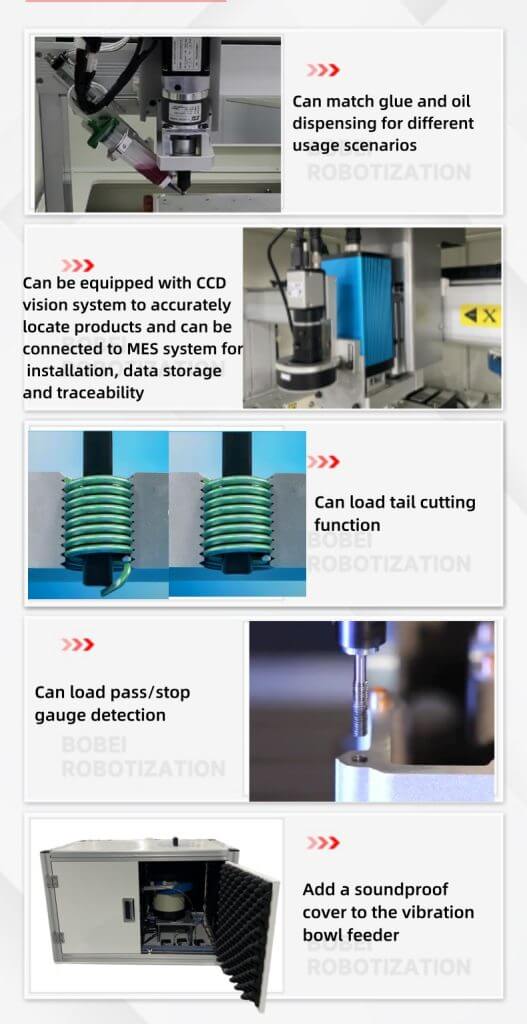

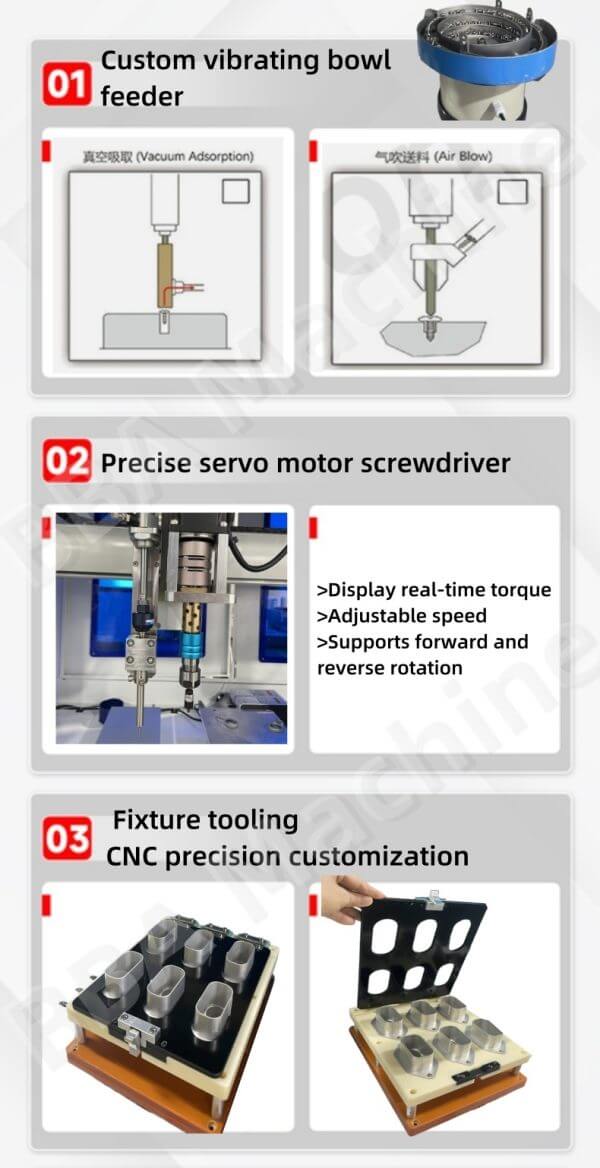

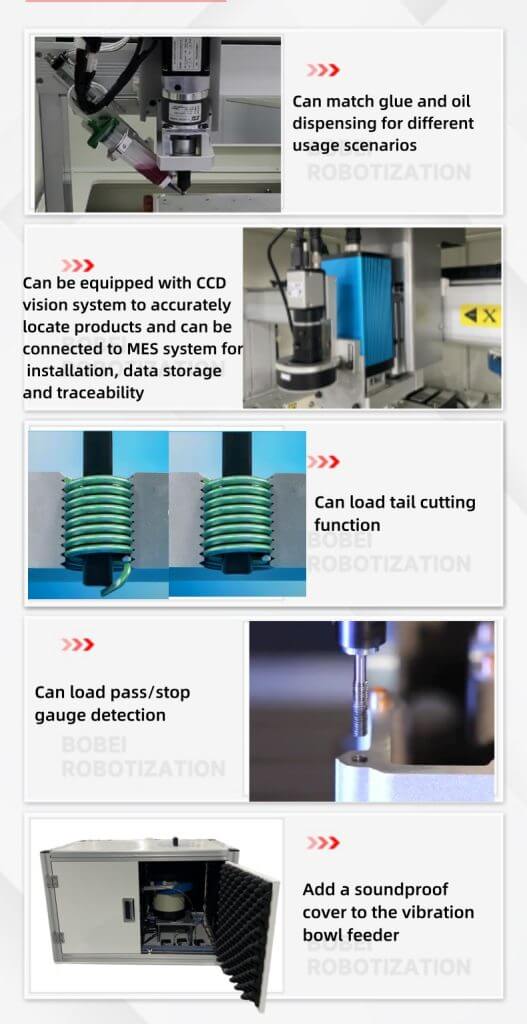

Product Description

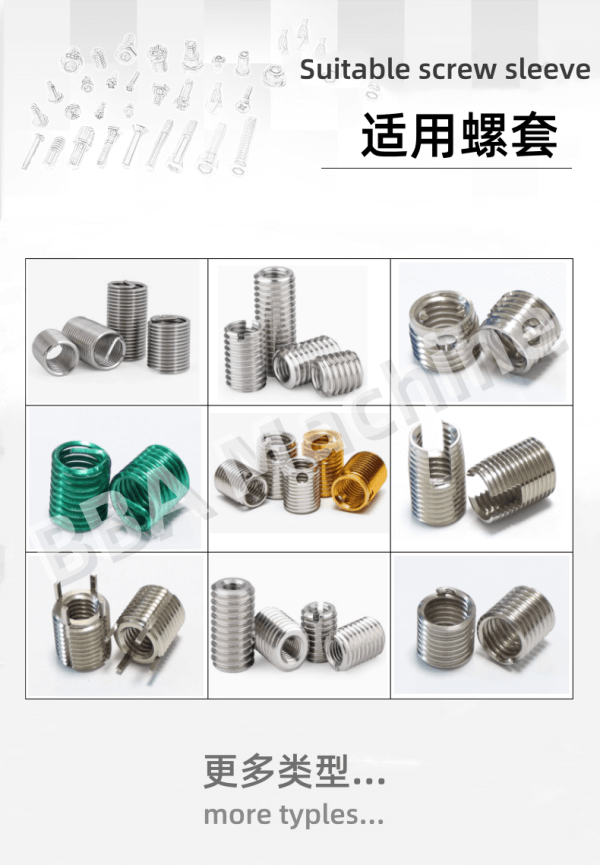

Applicable screws

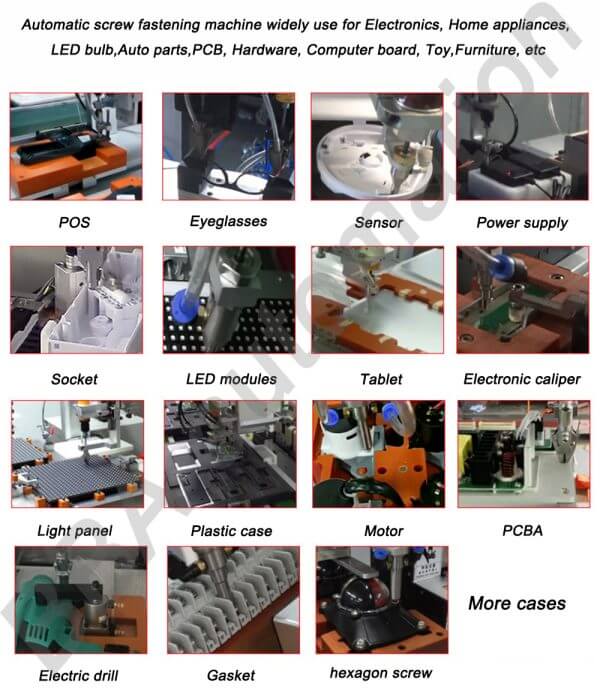

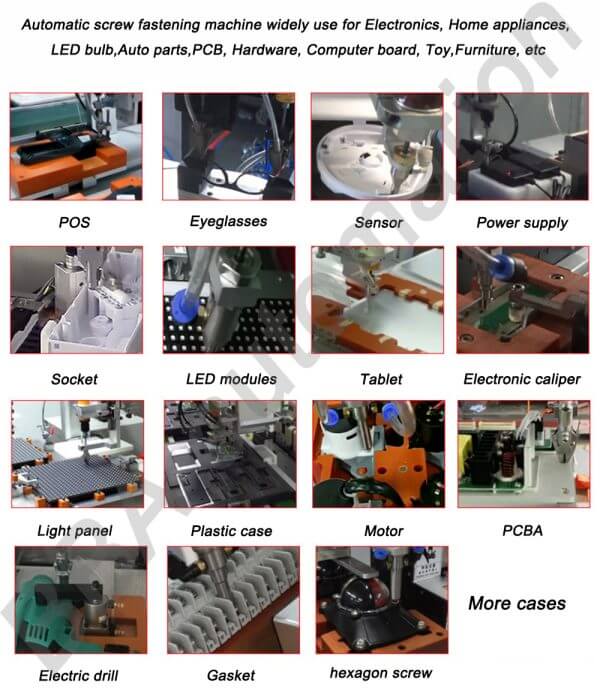

Customer case

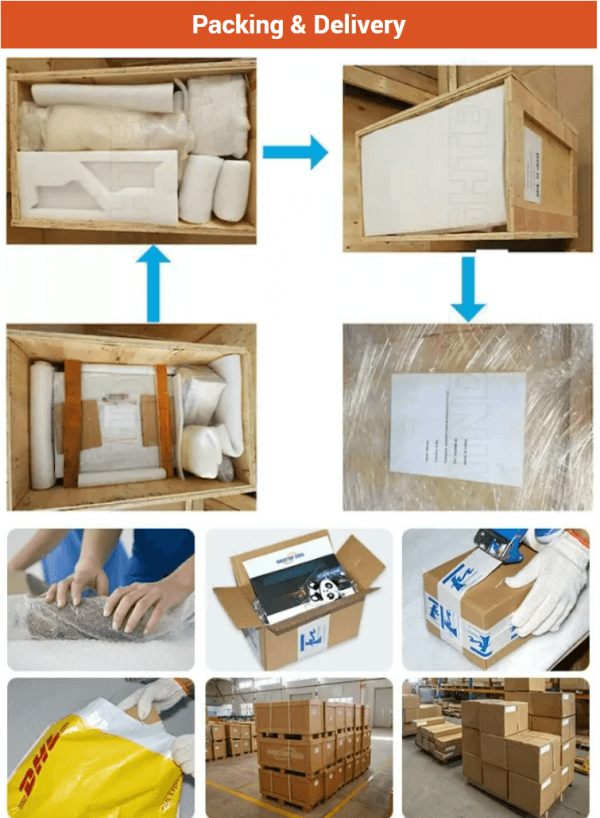

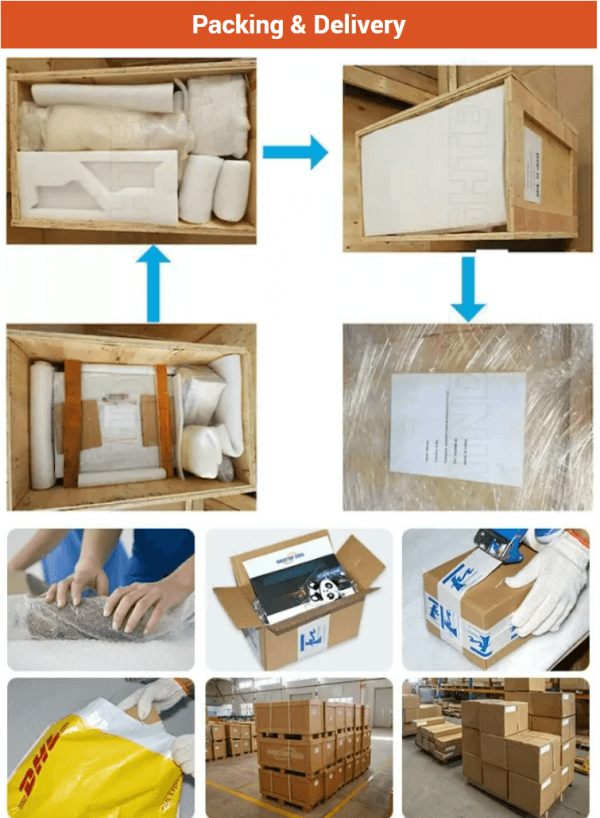

Package

| Voltage | AC110/220V 50/60HZ |

| Power | 1000W |

| Stroke | 500*400*400*100mm (X*Y*Z), can be customized |

| Movement speed | 10-500mm/S |

| Position accuracy | ±0.05mm/axis |

| Universal screw thread | M3-M10 |

| Screw thread height | 6-20mm |

| Screw thread material | Copper, Aluminum, Metal, Stainless steel |

| Screw thread type | Self-tapping thread, screw thread, steel thread |

| Transmission mode | Precision toothed belt+guide rail |

| Control panel | PLC+HMI screen |

| Conveying mode | Vibrating plate+direct vibrating track |

| Work efficiency | 6S/pcs (include cutting thread tail), details depends on thread size |

| Air pressure | 0.4-0.6Mpa |

| External port | RS232 |

| Program capacity | 12 groups, 20 points per group; can be customized |

| Work environment | Temperature: 5-40℃ Humidity: 20-90% |

| Weight | 580kg(Subject to the actual product) |

| External machine size (L*W*H) | 1150*1350*1650 mm(Can be customized) |

Product Description

Applicable screws

Customer case

Package