8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-10-05 Origin: BBA AUTOMATION

| Product Name | Applicable industries |

| Servo Screwdriver Robot | Home Appliance Production |

Automatic screw assembly machines have become indispensable in modern manufacturing, offering precision, speed, and reliability. These machines are designed to handle a variety of screwdriving tasks, reducing human error and increasing production efficiency. In this article, we will explore the different types of automatic screw assembly machines available in the market today.

One common type is the bench-top automatic screw feeder. These compact machines are ideal for small to medium-sized production lines. They are easy to set up and operate, making them a popular choice for businesses looking to automate their screwdriving processes without significant investment. Bench-top models often come with adjustable torque settings and can handle a range of screw sizes, providing flexibility for various applications.

Another type is the multi-spindle automatic screw assembly machine. Designed for high-volume production, these machines feature multiple spindles that can drive several screws simultaneously. This significantly reduces cycle times and boosts productivity. Multi-spindle machines are commonly used in industries such as automotive, electronics, and appliance manufacturing, where large quantities of products need to be assembled quickly and accurately.

For applications requiring mobility and flexibility, portable automatic screwdrivers are an excellent option. These handheld devices are equipped with automatic feed systems that supply screws continuously, allowing operators to work efficiently without manual handling. Portable models are often used in assembly lines where the workpiece is too large or cumbersome to move, or for on-site maintenance and repair tasks.

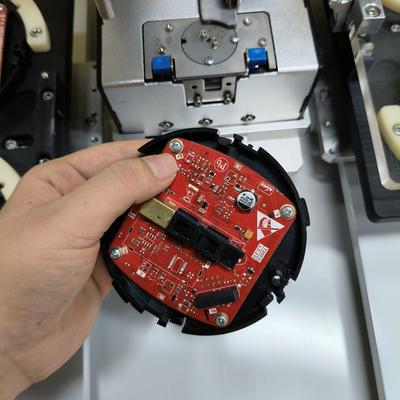

Additionally, there are fully integrated robotic screw assembly systems. These advanced machines combine robotic arms with automatic screw feeding and driving mechanisms. They are capable of performing complex assembly tasks with high precision and are often integrated into fully automated production lines. Robotic systems are ideal for industries that require consistent quality and minimal human intervention, such as aerospace and medical device manufacturing.

Lastly, customizable automatic screw assembly machines are available to meet specific production needs. These systems can be tailored to handle unique screw types, unusual workpiece geometries, or specialized assembly processes. Customizable machines offer the advantage of adaptability, ensuring that manufacturers can optimize their automation solutions for maximum efficiency and output.

In conclusion, the market offers a diverse range of automatic screw assembly machines, each suited to different production requirements. From bench-top feeders to robotic systems, these machines enhance manufacturing efficiency, improve product quality, and reduce labor costs. By understanding the various types available, businesses can select the right solution to meet their automation goals and stay competitive in the industry.