8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-10-05 Origin: BBA AUTOMATION

| Product Name | Applicable industries |

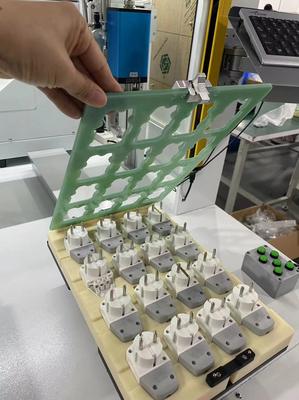

| Automatic Screw Feeder | Power Tool Assembly Lines |

Screw locking machines are essential in modern manufacturing and assembly processes, providing precision, reliability, and efficiency in securing threaded fasteners. For global buyers looking to invest in these systems, understanding key features, applications, and selection criteria is crucial. This guide offers insights into the world of screw locking technology, helping you make an informed decision tailored to your industrial needs.

Screw locking machines are designed to apply a consistent and accurate locking mechanism to threaded fasteners, preventing loosening due to vibration, thermal expansion, or other external factors. These systems utilize various methods, including adhesive application, mechanical deformation, or ultrasonic techniques, to ensure fasteners remain securely in place. Industries such as automotive, aerospace, electronics, and heavy machinery rely heavily on these machines to maintain product integrity and safety.

When evaluating screw locking machines, buyers should prioritize:

Screw locking machines are versatile and used in diverse sectors. In automotive manufacturing, they secure critical components like engine parts and braking systems. Aerospace applications demand extreme reliability for fasteners in aircraft structures and engines. Electronics assembly requires precision for small screws in devices, while heavy machinery depends on these systems for large-scale equipment stability. Understanding your specific application helps narrow down the ideal machine type.

Choosing the appropriate screw locking machine involves assessing production volume, fastener specifications, and environmental conditions. For high-volume operations, automated systems with multi-spindle capabilities offer superior efficiency. Low-volume or custom applications might benefit from semi-automatic or manual machines. Additionally, consider factors like energy consumption, footprint, and supplier support, including training and after-sales service. Requesting demonstrations or case studies can provide valuable insights into performance and suitability.

The screw locking machine industry is evolving with advancements in IoT and smart manufacturing. Modern systems often feature data logging, predictive maintenance alerts, and connectivity for Industry 4.0 integration. These innovations enhance productivity by reducing errors and enabling proactive adjustments. As sustainability gains importance, energy-efficient models and eco-friendly locking methods, such as water-based adhesives, are becoming more prevalent. Staying updated on these trends ensures long-term competitiveness and operational excellence.

Investing in the right screw locking machine is a strategic decision that impacts product quality, safety, and overall efficiency. By considering technical requirements, industry applications, and emerging technologies, global buyers can identify solutions that drive success in their automation processes. Always partner with reputable providers who offer comprehensive support and customization to meet unique challenges.