8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-10-04 Origin: BBA AUTOMATION

The landscape of industrial automation is undergoing a profound transformation, driven by the rapid advancement of multi-axis machines. These sophisticated systems are redefining what is possible in assembly lines, offering unprecedented levels of precision, flexibility, and efficiency. As industries strive for greater productivity and shorter time-to-market, the role of multi-axis automation becomes increasingly critical.

Traditional assembly systems often face limitations when dealing with complex components or intricate tasks. Multi-axis machines, equipped with five, six, or even more axes of motion, overcome these challenges effortlessly. They can approach a workpiece from virtually any angle, performing highly detailed operations with micron-level accuracy. This capability is indispensable for industries like electronics, aerospace, and medical devices, where the smallest deviation can have significant consequences. The result is a dramatic reduction in errors and a substantial improvement in final product quality.

In today's fast-paced market, the ability to quickly adapt to new product designs is a competitive advantage. Multi-axis machines are inherently flexible. Through simple software reprogramming, the same machine can be reconfigured to handle a completely different assembly process. This eliminates the need for costly and time-consuming physical retooling, enabling manufacturers to shift production lines with minimal downtime. This agility supports the growing trend of high-mix, low-volume production, allowing for greater customization without sacrificing efficiency.

The simultaneous movement across multiple axes allows these machines to perform complex sequences of operations in a single, fluid motion. Unlike traditional systems that might require moving a part between several stations, a multi-axis machine can often complete the entire process in one setup. This consolidation drastically reduces cycle times and minimizes handling, which not only speeds up production but also lowers the risk of damage to sensitive components. The overall equipment effectiveness (OEE) sees a remarkable improvement, leading to a stronger return on investment.

The future of multi-axis machines is deeply intertwined with Industry 4.0 principles. Modern systems are increasingly equipped with integrated sensors and vision systems, providing real-time data for process monitoring and quality control. This connectivity enables predictive maintenance, where potential issues are identified and addressed before they cause unplanned downtime. Furthermore, the data collected can be analyzed to continuously optimize assembly processes, creating a feedback loop that drives constant improvement in both quality and throughput.

As multi-axis technology continues to evolve, we are moving closer to the vision of the fully autonomous "lights-out" factory. These machines are becoming easier to program and more intuitive to operate, often through advanced human-machine interfaces (HMIs) and even augmented reality (AR) for setup and training. The synergy between multi-axis precision, adaptive robotics, and AI-driven data analysis is creating a new generation of assembly automation that is not only powerful but also intelligent and seamlessly integrated into the digital manufacturing ecosystem.

The adoption of multi-axis machines is no longer a luxury but a necessity for manufacturers aiming to stay at the forefront of innovation. They represent a fundamental shift towards more agile, precise, and intelligent production, truly shaping the future of assembly automation.

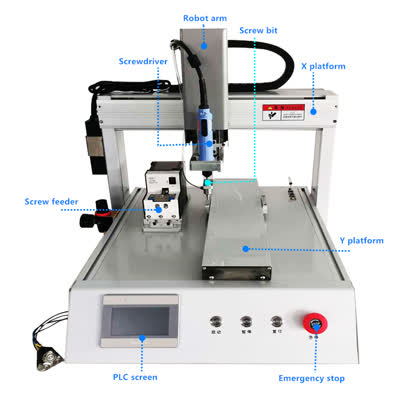

| Product Name | Applicable industries |

| Smart Screw Driving Machine | Smart Wearables Production |