8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-09-29 Origin: BBA AUTOMATION

In today's competitive manufacturing landscape, unplanned downtime is one of the most significant barriers to productivity and profitability. Even brief interruptions can cascade into costly delays, missed deadlines, and compromised product quality. While traditional automation has provided substantial improvements, a new generation of multi-axis automation systems is now setting a higher standard for operational reliability and efficiency.

Before delving into the solution, it's crucial to understand the problem's scope. Downtime in an industrial setting is rarely just a paused machine. It represents a complete halt in value creation. Costs accumulate from several areas simultaneously: lost production capacity, wasted raw materials, idle labor, and the potential for rushed, lower-quality work once operations resume. Furthermore, unexpected stoppages often necessitate emergency maintenance, which is more expensive and disruptive than scheduled, predictive upkeep.

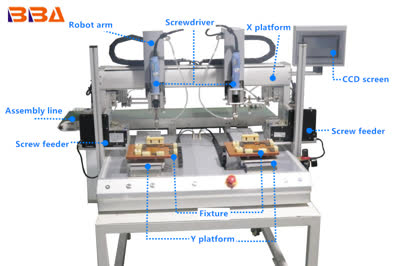

Multi-axis automation refers to advanced motion control systems that coordinate multiple movements—or axes—simultaneously with a high degree of precision. Unlike simpler systems that might move a tool along a single path (like a conveyor belt), multi-axis systems can control complex, synchronized motions across several planes. This is achieved through sophisticated controllers and software that harmonize the movement of robotic arms, gantries, and other actuators to perform intricate tasks with incredible speed and accuracy.

The architecture of multi-axis systems is inherently designed to promote continuous operation and rapid recovery. Here’s how it directly tackles downtime:

While the focus is on reducing downtime, the advantages of integrating multi-axis automation extend much further. Manufacturers often experience a substantial increase in overall production speed and throughput. The unparalleled precision also leads to higher and more consistent product quality. Furthermore, these systems can optimize material usage and reduce energy consumption per unit produced, contributing to lower operational costs and a smaller environmental footprint. Perhaps most importantly, they free human workers from repetitive, hazardous tasks, allowing them to be redeployed to higher-value roles that require problem-solving and oversight.

Adopting multi-axis automation is a strategic investment. Success hinges on a clear understanding of your specific production bottlenecks and goals. Partnering with a provider that offers robust technical support, comprehensive training, and reliable service is critical. A well-planned implementation, starting with a pilot project or a high-impact area, can demonstrate a rapid return on investment and pave the way for broader rollout.

In conclusion, as manufacturing pressures intensify, the ability to maintain continuous, efficient operation becomes a critical competitive advantage. Multi-axis automation is no longer a futuristic concept but a practical, accessible technology that provides a powerful solution to the perennial challenge of unplanned downtime. By enabling smarter, more precise, and more predictable operations, it lays the foundation for a more resilient and productive manufacturing future.

| Product Name | Applicable industries |

| Auto Screwdriver Machine | Medical Device Manufacturing |