8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-09-28 Origin: BBA AUTOMATION

| Product Name | Applicable industries |

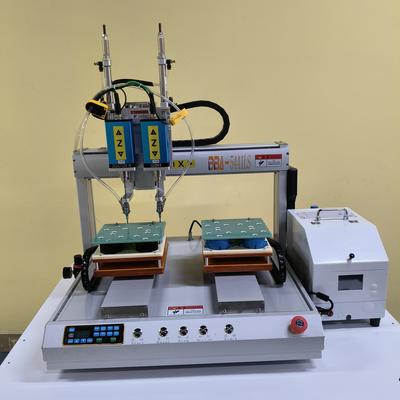

| Servo Screwdriver Robot | Consumer Electronics Assembly |

In the rapidly evolving world of industrial automation, flexibility and adaptability are key to maintaining a competitive edge. One of the most critical components enabling this versatility is the design of flexible arms used in robotic systems and automation machinery. These arms are engineered to perform a wide range of tasks across various industries, from assembly lines to complex material handling processes. The importance of flexible arm designs cannot be overstated, as they directly impact efficiency, precision, and the ability to customize automation solutions for diverse applications.

Flexible arms are designed with a focus on modularity and scalability. This means they can be easily adjusted or reconfigured to meet changing production demands without requiring complete system overhauls. For instance, in manufacturing environments where product lines frequently change, flexible arms allow for quick reprogramming and tooling adjustments. This reduces downtime and increases overall productivity. The use of advanced materials, such as lightweight composites and high-strength alloys, ensures that these arms are both durable and capable of high-speed operations with minimal wear and tear.

Another significant advantage of modern flexible arm designs is their integration with smart technologies. Many of these systems now feature embedded sensors and IoT connectivity, enabling real-time monitoring and data analytics. This allows operators to track performance metrics, predict maintenance needs, and optimize workflows dynamically. For example, in logistics and warehousing, flexible arms equipped with vision systems can identify, sort, and handle items of varying shapes and sizes with remarkable accuracy. This level of adaptability is essential in e-commerce and distribution centers, where order volumes and product types fluctuate rapidly.

The application spectrum for flexible arms is vast and continues to expand. In the automotive industry, they are used for tasks such as welding, painting, and assembly, where precision and repeatability are paramount. In pharmaceuticals, flexible arms assist in packaging, labeling, and even laboratory automation, ensuring compliance with strict hygiene and accuracy standards. The food and beverage sector also benefits from these designs, particularly in processes that require gentle handling or sanitary conditions. The ability to customize the range of motion, payload capacity, and end-effector attachments makes flexible arms indispensable across these diverse fields.

Looking ahead, the future of flexible arm designs is poised to embrace even greater levels of innovation. Advances in artificial intelligence and machine learning are expected to enhance the autonomy of these systems, enabling them to learn from their environments and make real-time adjustments. Collaborative robots, or cobots, which work alongside human operators, will further leverage flexible arm technology to create safer and more efficient workplaces. As industries continue to seek automation solutions that are both powerful and adaptable, the development of sophisticated flexible arms will remain at the forefront of industrial innovation.

In conclusion, flexible arm designs are a cornerstone of modern industrial automation, providing the versatility needed to meet the demands of diverse applications. By combining robust engineering with smart technology, these systems empower businesses to achieve higher levels of efficiency, customization, and scalability. As technology continues to evolve, flexible arms will undoubtedly play an increasingly vital role in shaping the future of automated industrial processes.