8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-09-21 Origin: BBA AUTOMATION

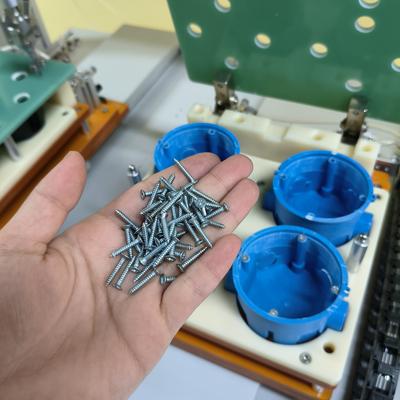

In the world of industrial automation, screw feeding mechanisms represent a critical yet often overlooked component of assembly systems. These mechanisms are responsible for the precise and efficient delivery of fasteners, ensuring that production lines operate smoothly and with minimal downtime. Recent innovations in this field have significantly enhanced the reliability, speed, and flexibility of screw feeding systems, making them more adaptable to the evolving demands of modern manufacturing.

One of the most notable advancements is the development of intelligent vision-guided screw feeding systems. Traditional systems often rely on mechanical or pneumatic methods to orient and feed screws, which can be prone to jams or misfeeds, especially with smaller or non-standard fasteners. Modern systems incorporate high-resolution cameras and machine learning algorithms to visually identify and verify the orientation of each screw before it is presented to the robot or assembly tool. This visual inspection drastically reduces error rates and allows for the handling of a wider variety of screw types and sizes without the need for costly mechanical changeovers. The system can instantly adapt to new fasteners simply by updating its software parameters, providing unparalleled flexibility for high-mix production environments.

Furthermore, advancements in drive and vibration technology have led to more efficient and gentle feeding processes. Newer bowl feeders utilize optimized vibration patterns and surface materials that minimize part-on-part contact and reduce the risk of damage to delicate screw finishes or threads. This is particularly crucial in industries like electronics or medical device manufacturing, where even a minor scratch can lead to product failure. Additionally, the integration of direct-drive servomotors in place of traditional electromagnetic drives allows for finer control over the feeding motion. This results in a quieter operation, reduced energy consumption, and the ability to precisely meter screws at very high speeds, matching the pace of today's rapid assembly lines.

Connectivity and data analytics represent another frontier of innovation. State-of-the-art screw feeding mechanisms are now equipped with IoT sensors that monitor key performance metrics such as feed rate, jam frequency, and motor torque in real-time. This data is streamed to a central monitoring system where it can be analyzed to predict maintenance needs before a failure occurs. For instance, a gradual increase in motor resistance can signal the need for bowl cleaning or component wear, allowing for proactive intervention during scheduled downtime. This shift from reactive to predictive maintenance not only prevents costly line stoppages but also extends the operational lifespan of the equipment, providing a significant return on investment.

Finally, the push for greater flexibility has given rise to modular and lean screw feeding designs. Instead of large, centralized feeding systems, manufacturers are adopting compact, decentralized units that can be placed directly at the point of use on the assembly line. These modules are easier to integrate and can be quickly swapped or reconfigured for different products. This modular approach supports the trend towards lean manufacturing and mass customization, allowing factories to quickly pivot between different products without halting production for extensive retooling.

In conclusion, innovations in screw feeding mechanisms are fundamentally transforming assembly automation. Through the integration of machine vision, advanced drive systems, IoT connectivity, and modular design, these systems are becoming smarter, more efficient, and more adaptable. These improvements are essential for manufacturers seeking to boost productivity, enhance product quality, and maintain a competitive edge in a dynamic industrial landscape.

| Product Name | Applicable industries |

| CNC Screw Fastener | Power Tool Assembly Lines |