8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-07-05 Origin: BBA AUTOMATION

Servo motor screw driving systems are essential components in modern industrial automation, offering precise control over motion and positioning in manufacturing and assembly processes. These systems combine servo motors and screw-driven mechanisms to achieve high accuracy, repeatability, and efficiency in linear and rotational movements. In this article, we explore the fundamentals of servo motor screw driving systems, their key components, and how they benefit various automation applications.

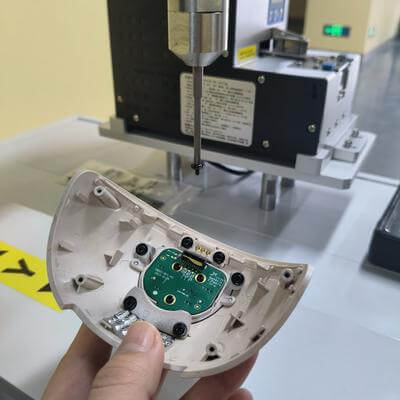

A servo motor screw driving system consists of a servo motor coupled with a screw drive mechanism, such as a ball screw or lead screw, to convert rotary motion into linear motion. Servo motors provide controlled movement with high torque and speed, while the screw mechanism ensures smooth and precise linear displacement. These systems are widely used in CNC machines, robotic arms, 3D printers, and automated assembly lines.

1. Servo Motor – The heart of the system, a servo motor delivers precise rotational motion with feedback control. It adjusts speed and position dynamically, making it ideal for automation tasks requiring high accuracy.

2. Screw Drive Mechanism – Ball screws and lead screws translate the motor's rotary motion into linear movement. Ball screws offer low friction and high efficiency, while lead screws provide cost-effective solutions for less demanding applications.

3. Linear Guide Rails – These support the moving parts, ensuring smooth and stable linear motion with minimal deflection.

4. Feedback Devices (Encoders) – Encoders send real-time position and speed data back to the controller, enabling closed-loop control for enhanced precision.

Servo motor screw driving systems provide several advantages in automation:

These systems are used across various industries, including:

Servo motor screw driving systems play a vital role in advancing automation by delivering speed, precision, and reliability. Whether in high-speed production or delicate assembly tasks, these systems enhance performance while reducing energy consumption and maintenance costs.

| Product Name | Applicable industries |

| Smart Screw Driving Machine | PCB and Circuit Board Assembly |