8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-06-21 Origin: BBA AUTOMATION

| Product Name | Applicable industries |

| Desktop Screwdriver Robot | Power Tool Assembly Lines |

In the rapidly evolving world of electronics manufacturing, precision and efficiency are paramount. As devices shrink in size while growing in complexity, traditional assembly methods face unprecedented challenges. This is where compact multi-axis tightening systems emerge as game-changers, revolutionizing how electronic components are secured during production.

Modern electronics demand microscopic accuracy. Circuit boards with high-density components, delicate connectors, and sensitive microchips require controlled, repeatable fastening. Under-tightening risks connection failures and vibration damage, while over-tightening can crack PCBs or deform housings. Conventional single-axis tools struggle to maintain consistent torque across multiple points, particularly in confined spaces where smartphones, wearables, and IoT devices leave minimal room for error.

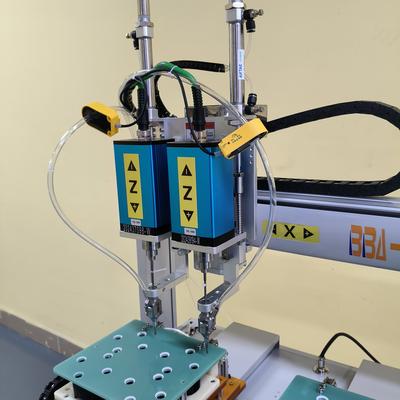

Compact multi-axis systems overcome spatial constraints by integrating multiple independently controlled tightening spindles into remarkably slim footprints. Unlike bulky traditional setups requiring separate tools for each fastener, these unified units perform simultaneous operations—fitting seamlessly into automated lines where real estate is precious. Their modular architecture allows tailored configurations, with 2 to 8+ spindles arranged linearly, radially, or in custom patterns to match assembly layouts perfectly.

Time is critical in high-volume electronics manufacturing. Multi-axis systems dramatically reduce cycle times by executing parallel fastening operations. While a single-axis tool might require 30 seconds to secure six screws sequentially, a multi-axis equivalent completes all six simultaneously in under five seconds—slashing process time by over 80%. This synchronization eliminates bottlenecks in PCB mounting, display installations, heat-sink attachments, and battery pack assemblies where multiple connections must be secured concurrently.

Smart torque management is where these systems truly excel. Each spindle features independent servo control with real-time monitoring, applying precise force profiles tailored for M1.6 micro-screws or fragile composite materials. Advanced systems incorporate angle monitoring and yield-point detection to prevent cross-threading, while automatic feed systems ensure continuous operation. Crucially, integrated data logging documents every fastener—tracking torque curves, sequence compliance, and quality metrics for full traceability.

Modern assembly lines thrive on adaptability. Compact multi-axis systems support quick-change tooling and programmable recipes, enabling seamless transitions between product variants. For automated settings, their compact dimensions allow smooth integration with SCARA robots or Cartesian positioners. In lean manufacturing layouts, they enable single-station multi-point fastening for LCD module installations or EMI-shield attachments, replacing multiple workstations and reducing floor space requirements by up to 40%.

As electronics assembly continues its trajectory toward miniaturization, compact multi-axis tightening systems solve critical challenges: enabling micron-level precision, accelerating throughput, ensuring data integrity, and maximizing production density. These sophisticated solutions represent not merely incremental improvements but fundamental advancements that will power next-generation manufacturing capabilities for increasingly complex electronic devices.