8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-06-19 Origin: BBA AUTOMATION

| Product Name | Applicable industries |

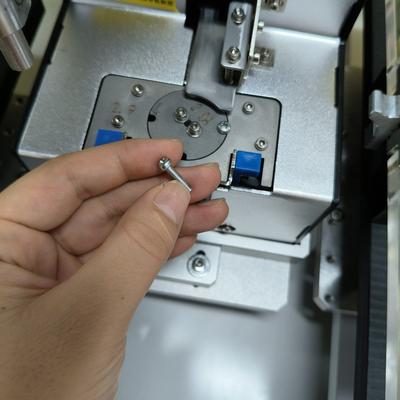

| Smart Screw Driving Machine | LED Lighting Industry |

Automatic screw locking machines have become indispensable assets in modern manufacturing ecosystems worldwide. These precision-engineered systems streamline assembly processes by delivering unmatched speed, accuracy, and repeatability in fastener installation. As industries from automotive to electronics increasingly adopt automated solutions, the global demand for these machines continues its upward trajectory.

The expansion of automated assembly is accelerating across key regions. Asian manufacturing hubs prioritize machines combining ultra-high speed with minimal footprint to maximize space utilization. European manufacturers demand precision engineering with integrated quality control systems adhering to strict ISO standards. North American industries seek modular platforms that integrate seamlessly into existing Industry 4.0 environments. Emerging economies show particular interest in robust, maintenance-friendly models capable of operating in diverse industrial conditions.

Cutting-edge innovations are propelling global competitiveness. Modern machines feature smart torque control systems that self-calibrate for different screw types and materials, eliminating manual adjustments. IoT-enabled sensors continuously monitor performance metrics like cycle times and error rates, transmitting real-time diagnostics to maintenance teams. Advanced vision systems now perform automated quality inspections during operation, rejecting defective assemblies at rates exceeding 99.95% accuracy.

Flexible robotic integration has become essential, with export models featuring universal interfaces that connect with diverse automation platforms. Sophisticated anti-jamming mechanisms automatically reorient misaligned screws, reducing downtime by up to 50%. Energy-efficient servo-drive technology meanwhile lowers operational costs - a critical advantage in regions with high electricity prices.

Successful international distribution requires meticulous attention to regional requirements. Export-compliant designs incorporate universal voltage compatibility (85-265V AC) and standardized safety circuits that meet both CE and UL certifications. Strategic packaging solutions protect sensitive components against humidity and shock during extended ocean shipments.

Technical documentation is meticulously localized with multilingual operation manuals, maintenance guides, and safety protocols. Forward-thinking suppliers establish regional technical support centers with native-language technicians, complemented by augmented reality troubleshooting platforms that enable remote guidance. Supply chain diversification has proven crucial for maintaining delivery timelines amidst geopolitical uncertainties, with leading exporters developing multiple manufacturing and logistics pathways.

Environmental considerations increasingly influence procurement decisions globally. Modern screw locking machines feature energy recovery systems that regenerate up to 25% of operational power during deceleration cycles. Lightweight aerospace-grade aluminum construction reduces both material waste and shipping emissions. European manufacturers especially value closed-loop lubrication systems that eliminate oil waste and maintenance downtime.

Emerging trends point toward hyper-customizable platforms that adapt to changing production needs without hardware modification. Self-optimizing machines that learn from operational data to prevent potential failures will soon become standard. Modular designs allowing field-upgradable components will extend equipment lifecycles to match evolving technical standards.

As global manufacturing becomes increasingly interconnected, automatic screw locking technology continues to break new ground. Suppliers who master the balance between technological sophistication, regional adaptation, and sustainable practices lead this dynamic sector. The capacity to deliver precision automation solutions across continents remains pivotal for supporting worldwide industrial advancement.