8618566785362 8618566785362 8618566785362 phoenix08@bbamachine.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: BBA AUTOMATION Publish Time: 2025-06-18 Origin: BBA AUTOMATION

The humble screwdriver, one of humanity's oldest mechanical tools, has undergone a revolution since the mid-20th century. While manual versions date back to the 1500s, the advent of automation propelled screw fastening into a new era. Early industrial robots in the 1960s handled basic tasks, but dedicated robotic screw driving systems only emerged as manufacturing precision demands increased.

By the 1980s, first-generation robotic screwdrivers entered assembly lines. These pneumatic or electric systems were rudimentary—fixed to workstations with minimal programmability. Engineers faced challenges with alignment and torque consistency, requiring precise part positioning. Vision systems were primitive, limiting adaptability to variable production environments.

The 1990s transformed capabilities through integrated sensing technology. Force-torque sensors enabled real-time feedback, allowing robots to detect cross-threading or stripped screws. Optical guidance systems improved positioning accuracy, while programmable logic controllers (PLCs) allowed rapid task switching. These strides expanded applications from automotive manufacturing to delicate electronics assembly.

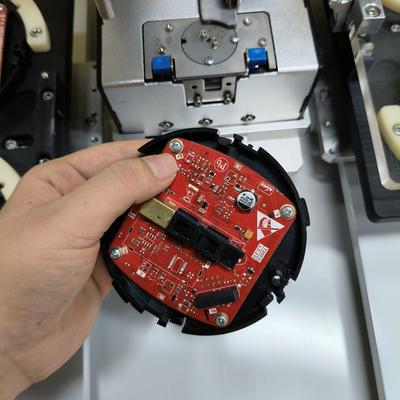

Modern robotic screwdrivers boast unprecedented sophistication. AI-driven error prediction analyzes torque curves to preempt failures. Collaborative robots (cobots) with safety sensors now work alongside humans on intricate tasks. Self-calibrating systems adjust to tool wear, and IoT connectivity enables real-time production analytics—monitoring each screw's insertion force cycle time.

Today’s solutions offer flexibility through modular designs. Interchangeable bits handle diverse screw types, while mobile robotic arms navigate between stations. Precision now reaches micrometer levels—critical for aerospace or medical device production where a single loose screw risks catastrophic failure.

The future points toward greater autonomy. Research focuses on robots learning optimal torque settings through machine learning rather than manual programming. Predictive maintenance algorithms will minimize downtime, while swarm robotics could enable multi-arm coordinated assembly. As miniaturization advances, microscopic screwdrivers may someday assemble nanotechnology invisible to the human eye.

From clunky pneumatic arms to AI-enhanced cobots, robotic screwdrivers exemplify how foundational tools evolve through innovation. They remain indispensable—transforming a simple act of rotation into a symphony of precision engineering driving modern manufacturing forward.

| Product Name | Applicable industries |

| Screw Locking Robot | Home Appliance Production |